Are you making one of the top 5 mistakes that plague wholesale

distributors? Download our free eBook to find out.

Carlo VassalloNY Produce Consultant

Carlo VassalloNY Produce Consultant

Brent EdwardsGeneral Manager

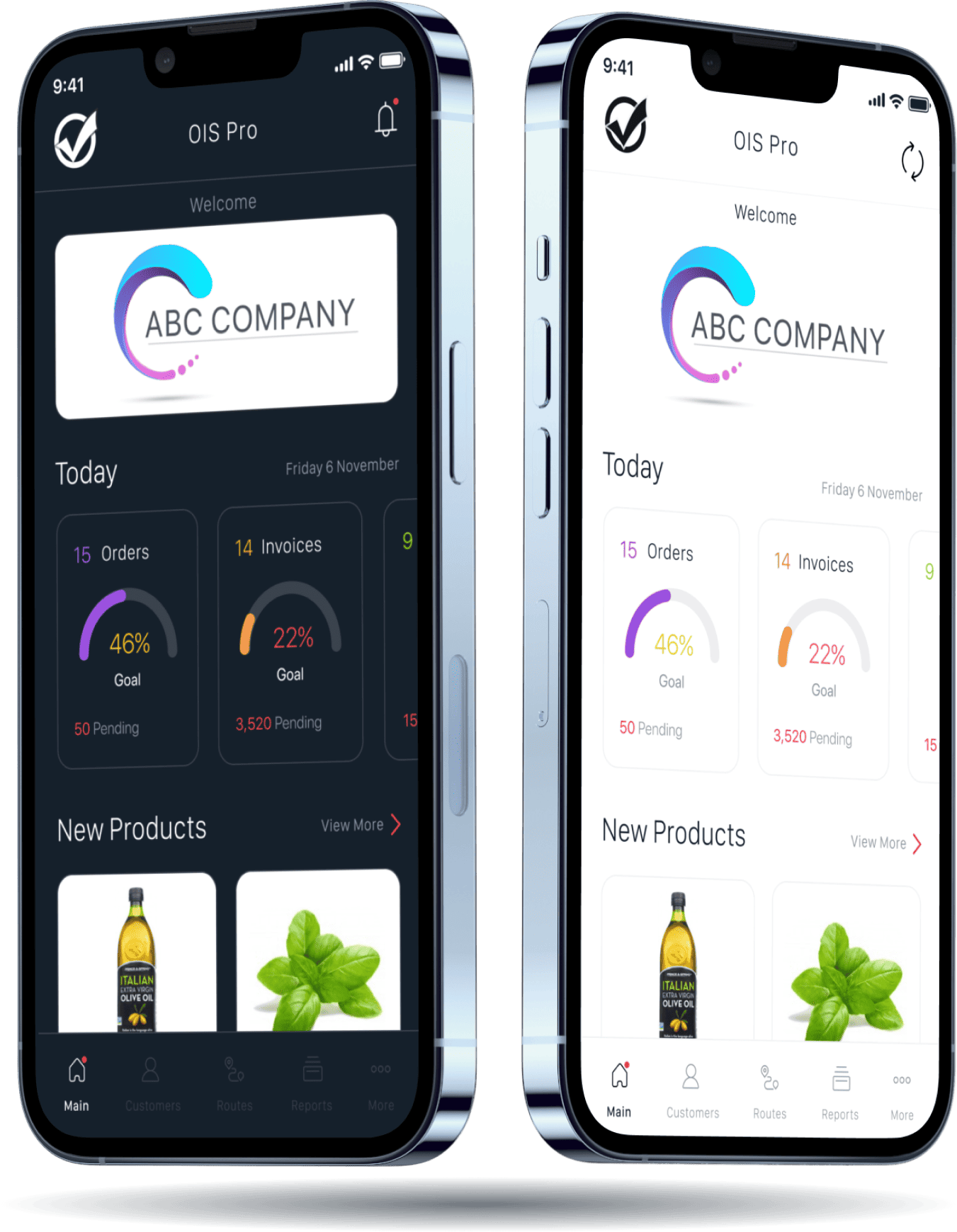

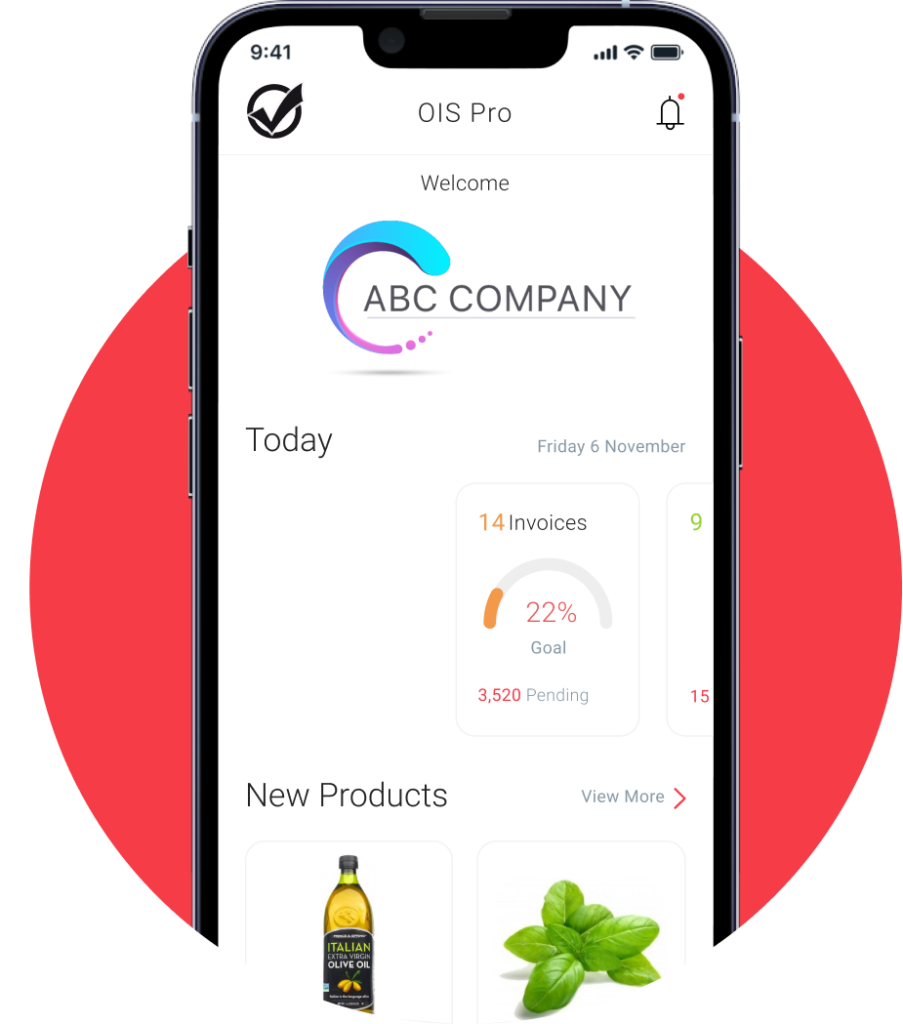

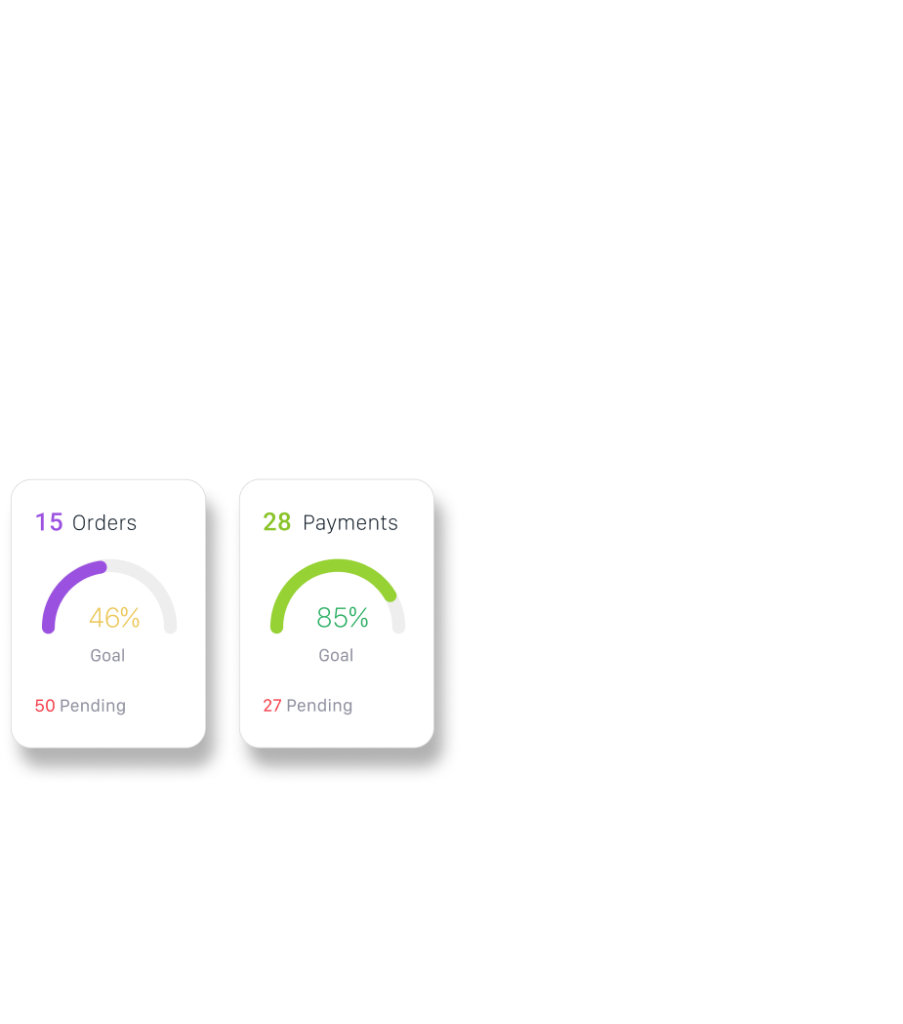

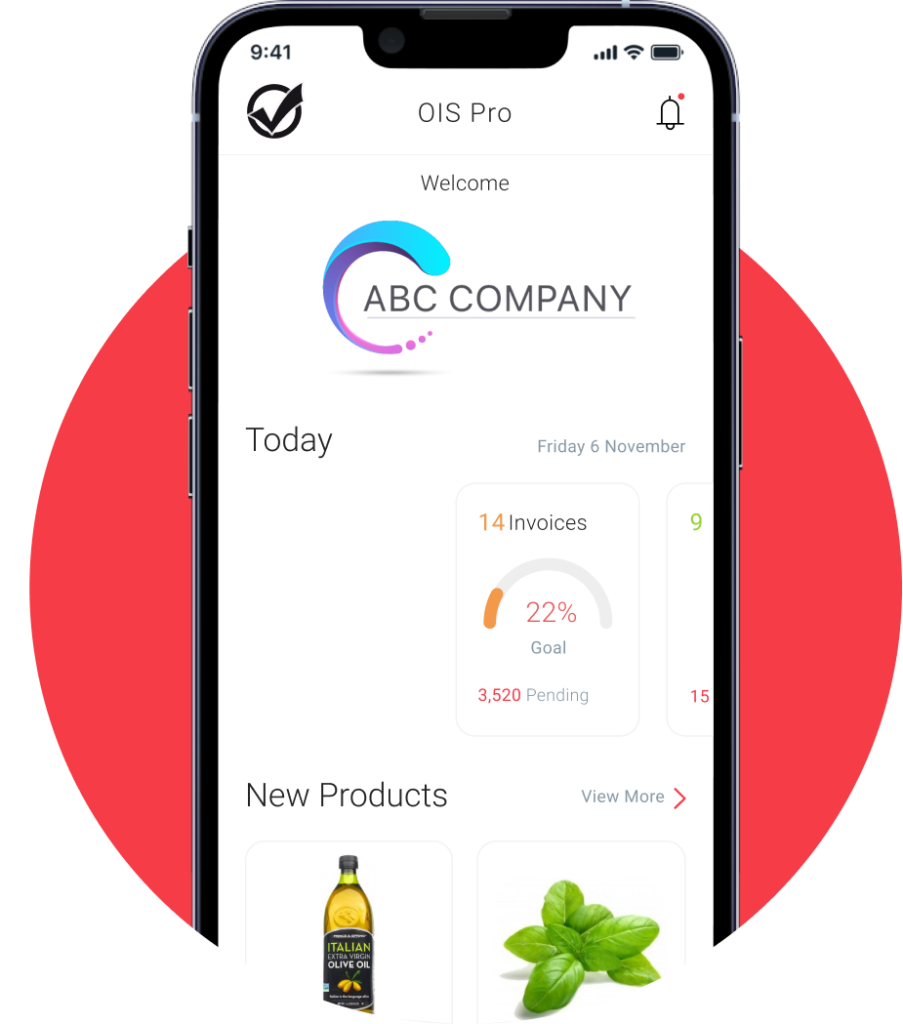

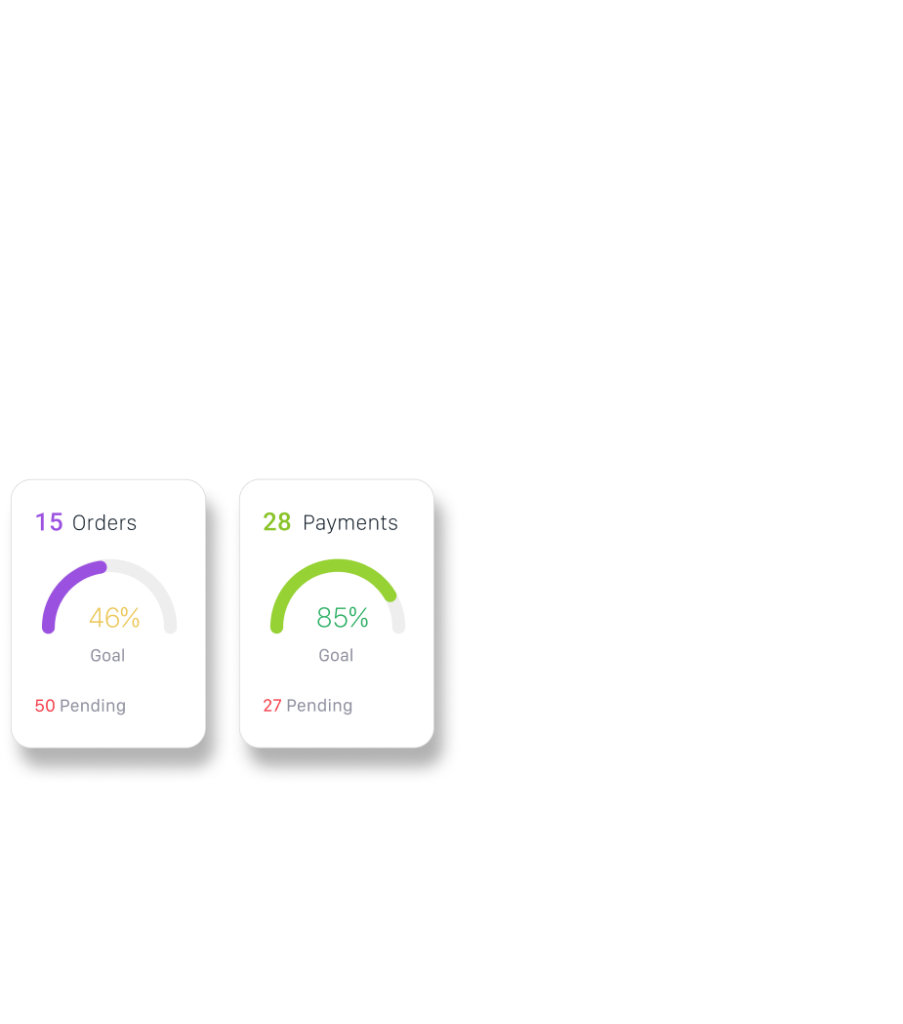

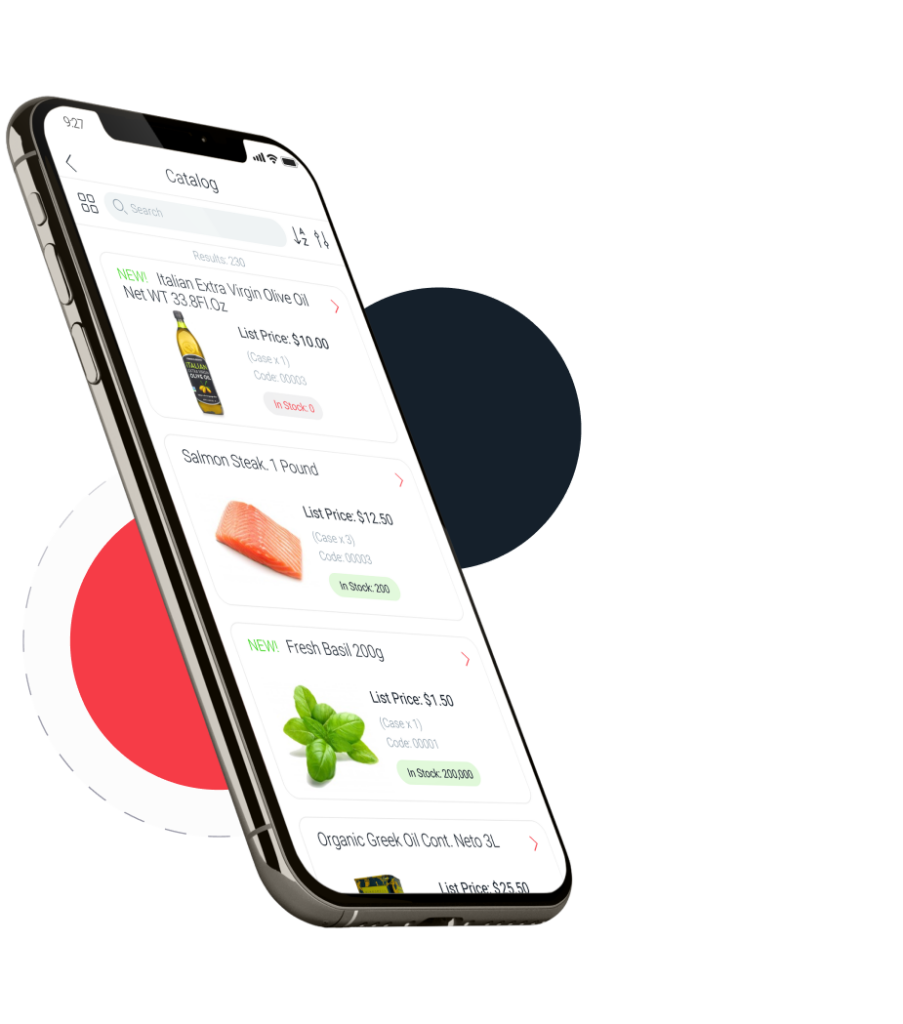

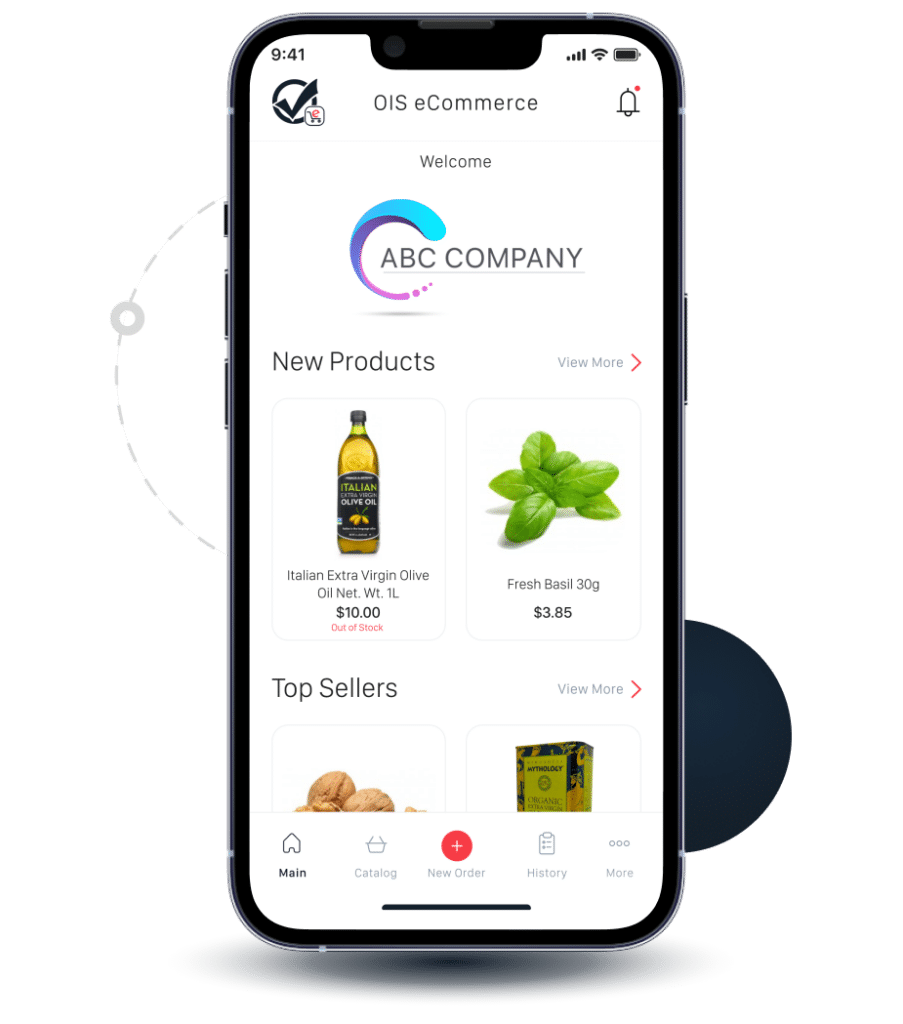

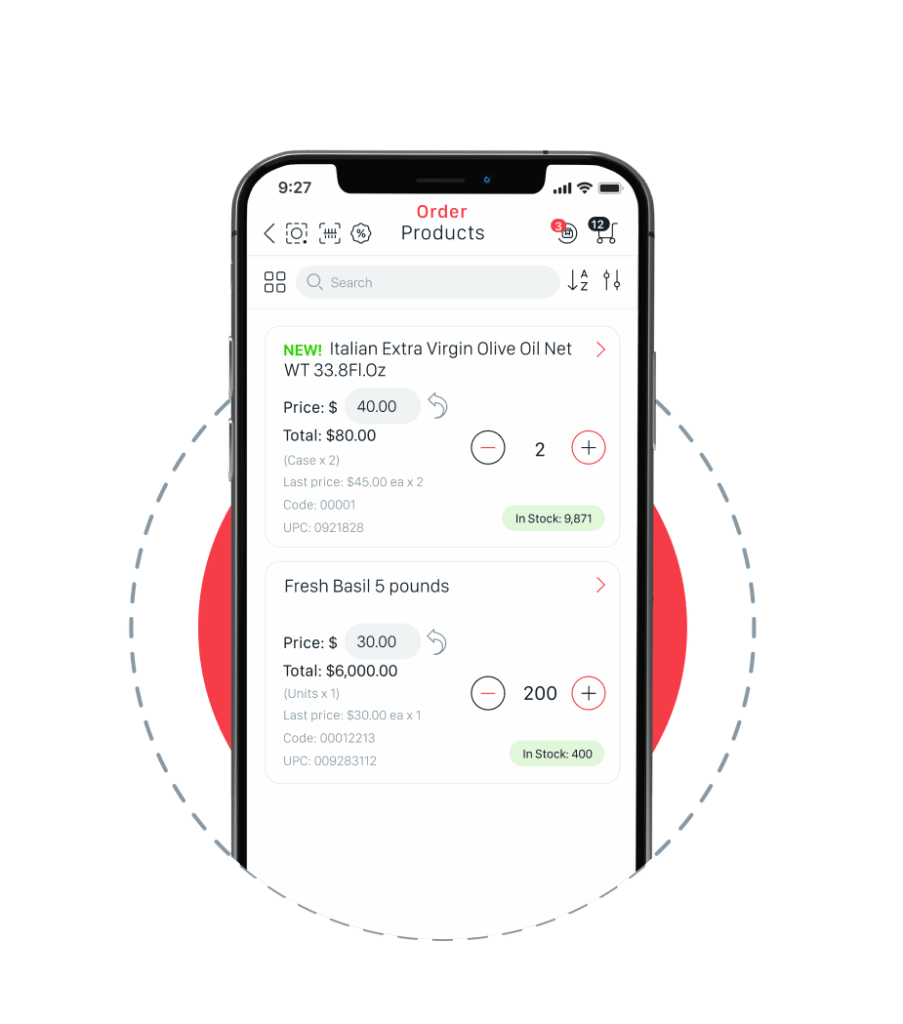

Impress customers by offering an app that’s easy-to-use, makes placing orders a breeze and sells 24/7. B2B eCommerce ordering increases efficiency, cost savings, improves accuracy and customer relationships.

Armando EsquivelOwner

Armando EsquivelOwner

Ron ClagnazSales Manager

This exclusive eBook is packed with real-world, data-driven concepts

that can help maximize your store visits and double your sales.

Get it for FREE – Today!

This exclusive eBook is packed with real-world, data-driven concepts that can help maximize your store visits and double your sales.

Get it for FREE – Today!